| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Model Number : E600

Place of Origin : MADE IN CHINA

Brand Name : KTC

Certification : CCC

MOQ : 10 pcs

Price : Negotiation

Packaging Details : 1PC/ PVC Packing, 10pcs PVC Packing/Pack...

Delivery Time : 1-35days

Payment Terms : T/T, L/C,Paypal...

Supply Ability : 10000pcs/week

Product Name : End Mills

Raw Material : GU25UF

Coating : AlTiN or TiSiN

Color : Black/Copper

Hardness : >92HRA

Cutting Diameter : Based on the flute length

Precision : High precision

Co : 12%

Grain size : 0.4 μm

Flutes No. : 4 Flutes

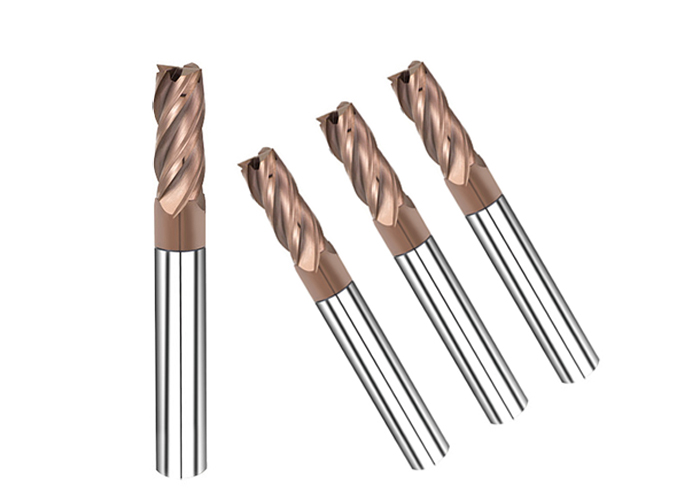

Aluminum Cutting Hard Milling End Mills Black or Copper Color Optional

Specifications

E600 high performance milling cutter series is made of domestic well-known high-quality fine grain tungsten steel material, with flexural strength of 4300mpa and grain size of 0.4 μm, and is coated with AlTiN or TiSiN imported from Switzerland. The cutter is designed with large helix angle, which can realize high-speed and efficient machining, especially suitable for medium and high carbon steel, die steel, pre-hardened steel and other materials processing. With high precision quality control, and full inspection, all E600 series end mills are delivered with 100% qualification rate.

| Material | GU25UF |

| WC | 88% |

| Co | 12% |

| TRS | >4300N/mm2 |

| Hardness | >92HRA |

| A.O.L | 50mm-150mm |

| Grain size | 0.4μm |

| Upto | HRC60 |

| Flutes No | 4 Flutes |

| Coating | AlTiN or TiSiN |

| Suitable for | Steel,stainless steel,nickel alloy,Titanuim alloy,cast iron,plastic and other materials |

Coating:

| Item | AlTiN | TiSiN |

| Hardness(HV): | 3200 | 3600 |

| Thickness(μm): | 2.5-3 | 3 |

| Oxidation Temp(°): | 900 | 1000 |

| frictional Coefficient: | 0.3 | 0.45 |

| Color: | Black | Copper |

Standard Sizes

| Size | Flute Length of End Mills(mm) | ||

| Flat end | Ball Nose | Round nose | |

| D1*D4*50 | 3 | 2 | 3 |

| D1.5*D4*50 | 4 | 3 | 4 |

| D2*D4*50 | 5 | 4 | 5 |

| D2.5*D4*50 | 6 | 5 | 6 |

| D3*D4*50 | 8 | 6 | 8 |

| D3*D3*50 | 8 | 6 | 8 |

| D3.5*D4*50 | 9 | 7 | 9 |

| D4*D4*50 | 10 | 8 | 10 |

| D1*D6*50 | 3 | 2 | 3 |

| D1.5*D6*50 | 4 | 3 | 4 |

| D2*D6*50 | 5 | 4 | 5 |

| D2.5*D6*50 | 6 | 5 | 6 |

| D3*D6*50 | 8 | 6 | 8 |

| D3.5*D6*50 | 9 | 7 | 9 |

| D4*D6*50 | 10 | 8 | 10 |

| D6*D6*50 | 13 | 10 | 13 |

| D6*D6*50 | 15 | 12 | 15 |

| D7*D8*60 | 17 | 14 | 17 |

| D8*D8*60 | 20 | 16 | 20 |

| D10*75 | 25 | 20 | 25 |

| D12*75 | 30 | 24 | 30 |

| D14*100 | 45 | 28 | 35 |

| D16*100 | 45 | 32 | 40 |

| D18*100 | 45 | 36 | 40 |

| D20*100 | 45 | 40 | 40 |

|

Flute Length of Extended End Mills(mm)

| |||

| D3*D4*75 | 12 | 6 | 12 |

| D4*D4*75 | 16 | 8 | 14 |

| D5*D6*75 | 18 | 10 | 15 |

| D6*D6*75 | 24 | 12 | 20 |

| D8*75 | 25 | 16 | 25 |

| D3*D4*100 | 12 | 6 | 15 |

| D4*D4*100 | 20 | 8 | 15 |

| D5*D6*100 | 20 | 10 | 20 |

| D6*D6*100 | 30 | 12 | 25 |

| D8*D8*100 | 35 | 16 | 30 |

| D10*100 | 40 | 20 | 30 |

| D12*100 | 45 | 24 | 35 |

| D6*D6*150 | 45 | 12 | 40 |

| D8*D8*150 | 50 | 16 | 45 |

| D10*150 | 55 | 20 | 50 |

| D12*150 | 55 | 24 | 55 |

| D14*150 | 60 | 28 | 60 |

| D16*150 | 70 | 32 | 65 |

| D18*150 | 70 | 36 | 70 |

| D20*150 | 70 | 40 | 70 |

FAQ

1. Where are your factory located? If I visit your factory, how can I go there?

Our factory located in Changzhou city, Jiangsu province.

2. What are your main products?

Our main products are carbide cutting tools, including end mill, face mill, drill bits etc.

3. What raw material you use?

We have rods with 3-4 types hardness, hrc45, hrc55, hrc60,hrc65.. Your work piece hardness decides what rods are suitable for.

5. How to ensure the quality?

We have precision detection machine, quality inspectors check cutters one by one.

6. How to deal with the cutters under verified?

These under verified cutters are all scraped.

7. I only have the drawings of work pieces? can you design cutters for me?

Yes, of course, show me work piece drawing, I will show you cutters’ drawing.

9. How long can you deliver goods?

If we have stock, goods will be shipped by next day, if not in stock, 7-35 days.

10. Can I choose the color of plastic pipe?

Yes, we have such as black, blue, red, yellow etc. color.

11. Can you make stickers with our logo and laser on cutters’ shanks?

Yes. We can print stickers with your logo and laser on shanks.

|

|

Steel Cutting Hard Milling End Mills Black or Copper Color Optional Images |